In the world of precision machining, the selection of the right cutting tools can significantly impact a company’s bottom line. When it comes to working with robust materials like steel and cast iron, the role of end mills becomes even more crucial.

In this post, we’ll explore the economic advantages of 4 flute variable end mills, specifically tailored for machining steel and cast iron components.

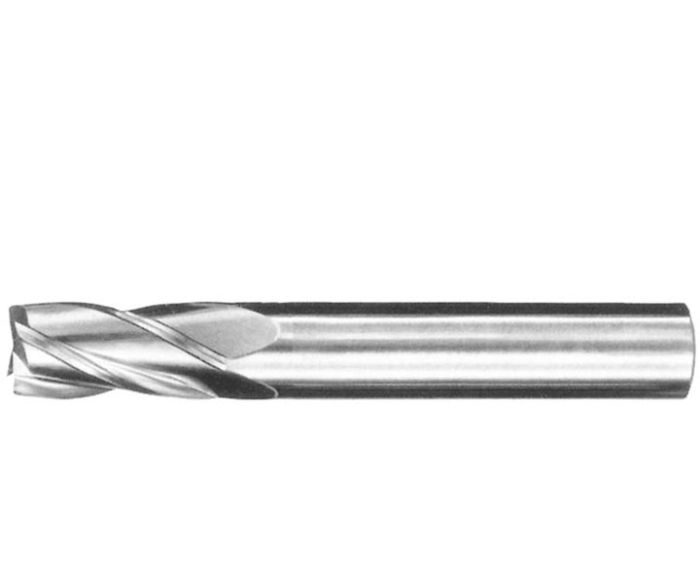

Understanding 4 Flute Variable End Mills

4 flute variable end mills are high-performance cutting tools designed with multiple flutes to enhance cutting efficiency. Unlike traditional three flute end mills, 4 flute end mills offer improved chip evacuation, ensuring smoother and more stable machining in tough materials.

Their variable helix design minimizes chatter and vibration during cutting, allowing for deeper and faster cuts, making them ideal for steel and cast iron applications.

Cost Savings through Higher Efficiency

One of the key economic benefits of using 4 flute variable end mills for steel and cast iron machining is the improved machining efficiency they provide. With higher material removal rates and reduced machining times, manufacturers experience significant cost savings.

Whether you’re involved in high-volume production or precision machining, these end mills can optimize your manufacturing process and lower production costs considerably.

Extended Tool Life and Reduced Downtime

Due to their robust construction and wear-resistant properties, 4 flute variable end mills offer extended tool life compared to traditional three-flute end mills. This longevity translates to fewer tool replacements and reduced downtime, resulting in substantial savings over time. Manufacturers can focus on uninterrupted production, meeting deadlines, and achieving higher output rates without frequent tool changes.

Precision and Quality in Machining

4 flute variable end mills deliver exceptional precision and superior surface finish when machining steel and cast iron. The ability to produce high-quality components in the first pass reduces the need for secondary operations, further lowering production costs. Manufacturers can rely on these end mills to consistently deliver precise results, meeting stringent quality standards and reducing material wastage.

Cost-Effectiveness in High-Volume Production

For industries requiring high-volume production, 4 flute variable end mills prove exceptionally cost-effective. Their ability to maintain efficiency and tool life in continuous manufacturing processes ensures optimal performance and cost savings on a large scale. Manufacturers can produce more components per tool, minimizing overall tooling expenses and increasing profitability.

Choosing the Right 4 Flute Variable End Mills

Selecting the appropriate 4 flute variable end mills is crucial for achieving the desired cost savings and longevity. Consider factors like material composition, cutting parameters, and coating options to ensure optimal performance. We recommend trusted manufacturers like Burrs4less, known for producing high-quality 4 flute variable end mills specifically designed for steel and cast iron machining.

Maintenance and Care

Proper maintenance and care play a vital role in maximizing the benefits of 4 flute variable end mills. Regular cleaning, storage in appropriate conditions, and careful handling can extend their life even further. By incorporating good maintenance practices, manufacturers can enjoy continued cost savings and prolonged tool longevity.

Summing Up:

4 flute variable end mills for steel and cast iron machining offer substantial economic benefits through improved efficiency, extended tool life, and enhanced product quality. Embrace the advantages of 4 flute variable end mills and optimize your manufacturing operations for success.

One of the significant advantages of 4 flute variable end mills is their improved efficiency. The multiple flutes distribute the cutting forces evenly, reducing chatter and vibration during machining. This leads to smoother cuts, higher material removal rates, and ultimately shorter cycle times, optimizing the overall manufacturing process.

Moreover, the extended tool life offered by these end mills significantly reduces the need for frequent tool changes. This not only saves time but also lowers production costs, as fewer tools are required for the same job. Additionally, the enhanced product quality achieved through precise machining helps eliminate the need for rework, further contributing to cost savings and increasing customer satisfaction.

By embracing the advantages of 4 flute variable end mills, manufacturers can stay competitive in today’s demanding market. Whether you are running a small-scale workshop or a large industrial facility, optimizing your machining operations with these cutting-edge tools will undoubtedly lead to success and profitability. Keep your business ahead of the curve by incorporating 4 flute variable end mills into your metalworking arsenal and experience the transformative impact on your productivity and bottom line.